Most experts agree that spray polyurethane foam is a revolutionary product. What they don’t always agree on is the way it’s installed and integrated into a building assembly. To shed some light on this debate, energy-efficient building expert Bruce Harley (Westborough, Mass.) and architect Peter Pfeiffer (Austin, Texas) explain how they use spray polyurethane foam to insulate the homes they build.

Peter Pfeiffer

Peter Pfeiffer

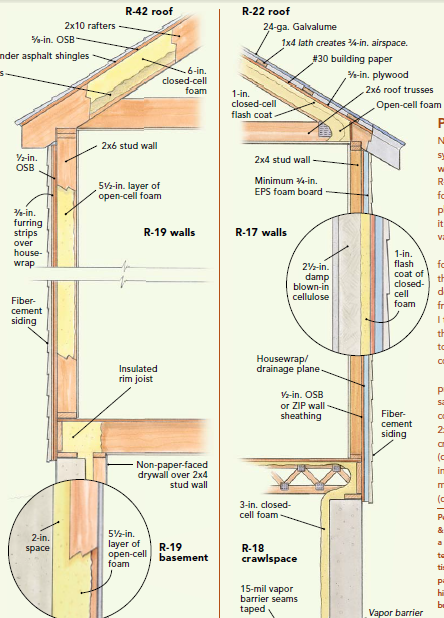

No other insulation system I am familiar with provides the real R-value that spray foam does, accomplishes the air-sealing it does, or thwarts vapor flow as well. Closed-cell spray foam greatly reduces the chance for condensation within the framing of a home. I think it is critical that houses be built to thwart vapor flow correctly. I insulate all homes pretty much the same. However, in colder climates, I use 2×6 exterior walls, create a cold roof (drawing p. 36), and insulate the basement or crawlspace, Peter Pfeiffer of Barley & Pfeiffer Architects is a LEED-accredited architect and building scientist who has spent the past 30 years developing high-performance building-design strategies.

Bruce Harley

Spray foam can be a great material, but understanding its use is often hindered by overeager installers who emphasize the magic rather than the real properties of the products. Too often, I hear from clients that “my dealer said that I only need 2 in. to 4 in. of foam in my walls because it performs just like R-40 fiberglass and prevents any possible moisture problems.” It’s just not true. An R-12 wall is an R-12 wall, no matter what the material is. Cutting air leakage saves energy, but it doesn’t make up for a low R-value. For best performance, I use spray foam in a variety of ways when designing the shell of a home. Here’s one example. Bruce Harley of Conservation Services Group is an energy-efficient construction expert and author of Cut Your Energy Bills Now (The Taunton Press, 2008).

1800 West 6th Street,

Austin, Texas 78703.

© – All Rights Reserved – Barley Pfeiffer – Designed By: Parentheses